Band Saw Aldi

Ryobi

Scroll saws allow you to cut through the wood. This means scroll saws donít require you to make an entry point cut.

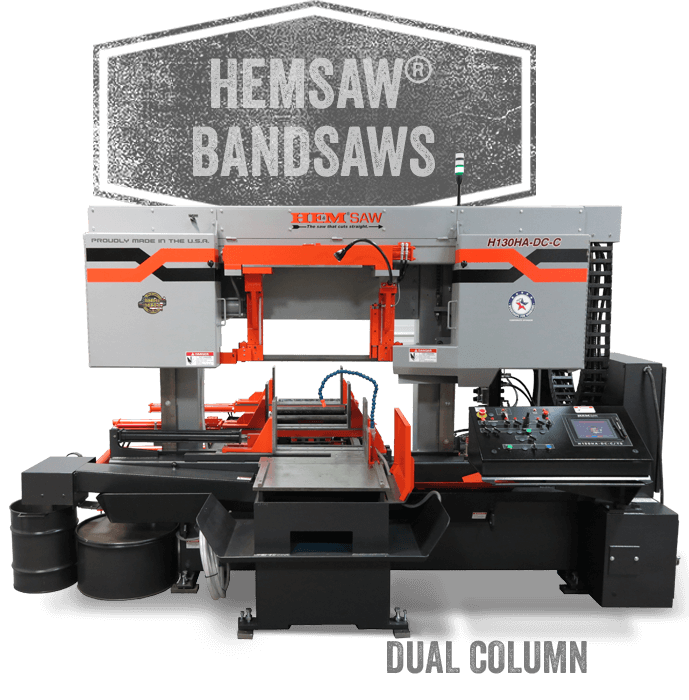

A much more expensive bandsaw can be bought. You can buy a more expensive band saw, but this is all you need for DIYers.